PP Hollow Tsev Formwork Extrusion Kab

PP Hollow Tsev Formworkyog ib qho khoom txuag hluav taws xob thiab ntsuab ib puag ncig tiv thaiv khoom. Nws yog lwm tiam tshiab khoom tom qab ntoo formwork, ua ke steel formwork, xyoob ntoo glued formwork thiab tag nrho cov hlau loj formwork. Nws tuaj yeem hloov pauv cov tsoos steel formwork thiab ntoo formwork, nrog kev txuag hluav taws xob, kev tiv thaiv ib puag ncig thiab tus nqi qis amortization.

Yim qhov zoo

1. Ua kom du thiab du. Lub formwork yuav tsum tau spliced nruj nreem thiab smoothly. Tom qab demoulding, qhov saum npoo thiab tiav ntawm cov pob zeb ua vaj tse yuav tsum tshaj qhov kev xav tau ntawm kev ncaj ncees uas twb muaj lawm formwork. Tsis tas yuav tsum tau plastering theem nrab, uas txuag kev ua haujlwm thiab cov ntaub ntawv.

2. Lub teeb thiab hnav yooj yim. Nrog lub teeb yuag thiab muaj zog cov txheej txheem adaptability, nws tuaj yeem sawed, npaj, drilled thiab nailed, thiab tuaj yeem tsim cov duab geometry ntawm lub siab nyiam kom tau raws li qhov xav tau ntawm lub tsev formwork ntawm ntau yam duab.

3. Yooj yim demoulding. Lub pob zeb tsis lo rau ntawm qhov chaw slab thiab tsis xav tau tso tawm tus neeg sawv cev. Nws yog ib qho yooj yim rau demould thiab tshem tawm tshauv.

4. ruaj khov thiab huab cua resistant. Lub zog txhua yam muaj zog, tsis muaj qhov o, tawg, deformation, ruaj khov loj, alkali tsis kam, tiv thaiv corrosion, nplaim retardant thiab waterproof, nas thiab kab tshuaj tua kab nyob rau hauv qhov kub ntawm -20 ℃ to + 60 ℃.

5. Yooj yim rau tu. Lub formwork tsis nqus dej thiab tsis xav tau kev saib xyuas tshwj xeeb lossis khaws cia.

6. Muaj zog sib txawv. Hom, hom thiab specification tuaj yeem kho raws li qhov yuav tsum tau ua ntawm kev tsim kho engineering.

7. Txo cov nqi. Lub sij hawm tig rov qab yog ntau, lub dav hlau formwork tsis pub tsawg tshaj 30 zaug, thiab cov kab nqaj kab formwork tsis tsawg tshaj li 40 zaug, nrog cov nqi siv tsawg.

8. Kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig. Tag nrho cov khoom seem thiab cov ntaub ntawv pov tseg tuaj yeem rov ua dua.

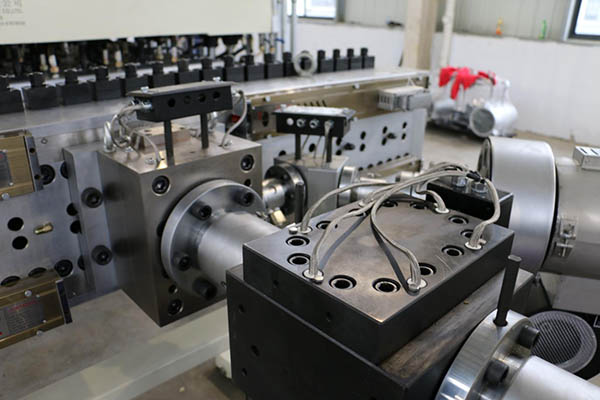

JWELL tsim PP ib pwm ob npaug ntawm lub tsev tsim cov kab ntau lawm raws li kev cai 915mm ib kab ntau lawm, uas tsis tsuas yog tuaj yeem ua tau raws li qhov xav tau ntawm cov zis loj thiab tsis muaj zog.

Yam ntxwv

1. Peb txheej coextrusion ntau lawm kab

2. Peb txheej composite distributor

3. Multi-layer lattice pwm

4. Peb qib board

5. Combined tsheb laij teb

6. Tsis siv neeg tsau ntev txiav tshuab

Main technical specification

|

Qauv |

Khoom siv |

Extruder specification |

Cov khoom dav (mm) |

thickness (mm) |

Peev xwm (kg / h) |

|

JWS 130(80)-1320 |

PP hloov khoom siv |

JWS 130/35, JWS 80/35 |

915/1220 ib |

12-14/15-17 dr hab |

450-500 |

|

JWS 150(80)-2000 |

PP hloov khoom siv |

JWS 150/35, JWS 80/35 |

915 * 2 |

12-14/15-17 dr hab |

550-600 |

|

CJWH85(80/52)-2000 |

PP hloov khoom siv |

CJWH85, CJWH52/JWS 80 |

915 * 2 |

12-14/15-17 dr hab |

600-700 Nws |

Nco tseg: Cov kev qhia tshwj xeeb yuav hloov pauv yam tsis tau ceeb toom ua ntej.

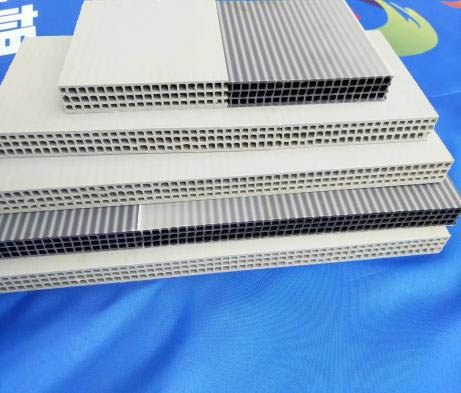

Khoom duab tso saib

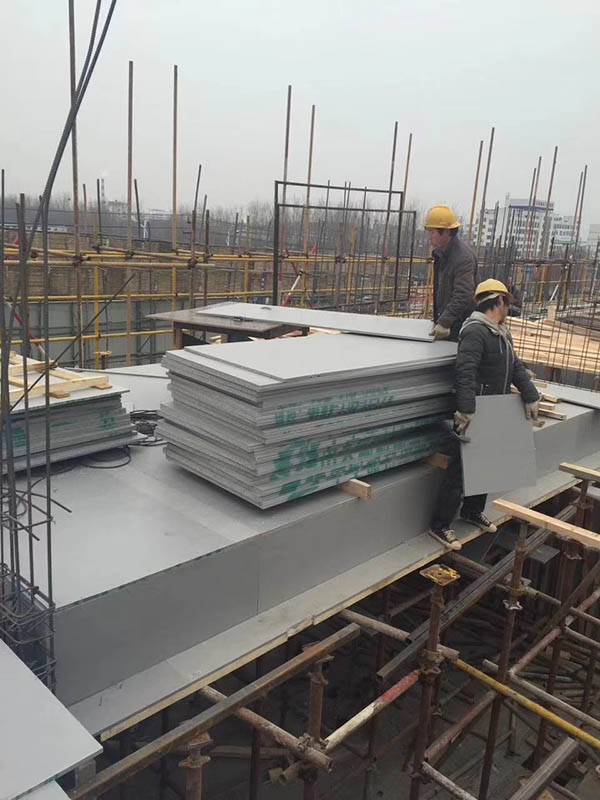

Qhov chaw tsim kho